Intuitive Interfaces

Working together

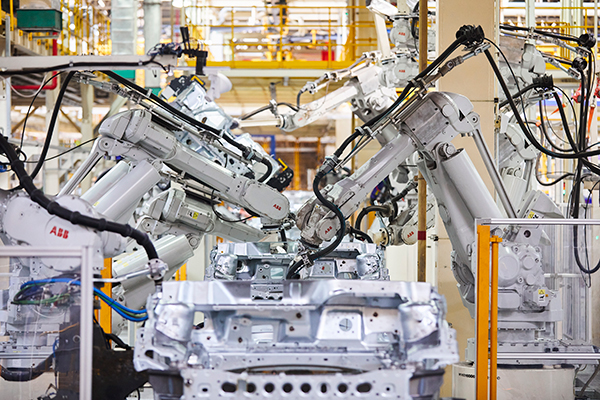

More than ever, we are controlling the devices around us through new, improved interfaces. Via voice, movement or even our presence, we are producing the desired response from phones, smart homes and other devices. Additionally, we have also become used to the simplicity and benefits of ‘Plug and Play’ between devices. We point our phone at our new smart speaker and the configuration is automatic and painless. We are bringing these simplified experiences to the factory floor

These innovations could include motion signals through imaging sensors, speech control, voice commands, etc. and all solutions should also factor in reliability, practicality and scalability.

Do you have a novel interface (human to machine) or an innovative solution to enable different devices to work together (machine to machine) easily, quickly, reliably and securely?

Solutions could include or involve quickly changing tools or end effectors based on job requirements, integration of third-party components or machines or the easy addition of new sensors or control units.

If your application to this challenge is successful, we would ask that you demonstrate your solution/prototype during the virtual pitch event and focus the collaboration on an integrated demonstration connecting ABB robots and ABB or third-party assets.

APPLY

Digitalization

Data value

The digital transformation of industries is leading towards a future industrial system that uses data to deliver high value to customers around the globe. Industries, to be competitive, are looking to increase their collection and use of data to improve asset utilization and performance, resource and process management.

We are looking for methods, tools, and systems for enhancing user-experience and increasing product-value in the end-to-end business lifecycle. This could include but are not limited to data analytics, decision support, pattern recognition in data and signals, predictive maintenance, and anomaly detection.

Do you have a solution which can intelligently improve the use of data for enhancing user-experience or increasing product value?

Solutions could include or involve AI or ML applications or approaches, preventative and predictive maintenance, machine monitoring and feedback solutions or machine and fleet management systems.

If your application to this challenge is successful, we would ask that you demonstrate your solution/prototype during the virtual pitch event and focus the collaboration on an integrated demonstration using ABB robotics assets.

APPLY

Mobility

Get moving

Henry Ford ushered in the age of assembly lines and highly efficient production. Fast forward 100 years and the new age of flexible production and customization is driving the development of distributed and easily reconfigurable production lines. In this environment, parts and machines themselves will move around the production environment with intelligence and safety, cooperating with other machines and humans alike. In factories, mobile units ferry parts from warehouse to production floor while robot manipulators move to their next task. In healthcare and the lab environment, mobile robots navigate samples around a lab as they move through the analysis process. This requires innovative capabilities in vision, collision avoidance, fleet management, and free navigation systems.

Do you have a solution which can enable this mobile, distributed new way of working and get robots off the line and moving around?

Solutions could include or involve mobile robots or AGVs and/or the enabling technologies to get robots moving such as vision, SLAM, collision avoidance etc.

If your application to this challenge is successful, we would ask that you demonstrate your mobility solution with any device during the virtual pitch event and focus the collaboration on an integrated demonstration moving an ABB robot or robotic accessory.

APPLY